Visiting KunShan

The living spaces are also big building blocks too, so there is literally no break in big development after big development, with very few clusters of independent shops and even fewer social sites apart from those occasionally engineered into the grounds of the many companies.In all honesty, it actually felt numbing for someone from a country where everything is packed tightly and has a constant variation, but on reflection, considering the people that live and work on the industrial estates, the enclosed system certainly beats many alternatives of (low) paid work for the many Chinese. It could be a lot worse: at least the MSI plant is a clean, well managed and secure facility.

You see, (most) of the workforce lives on site and does the job seasonally, while sending money back to families who often live in the more rural West. It may not pay that much, at around 1,000 Yuan per month (£66) and you have to share a room with seven others but if that newly built roof over your head costs you only a tenth of that, you can send quite a bit home.

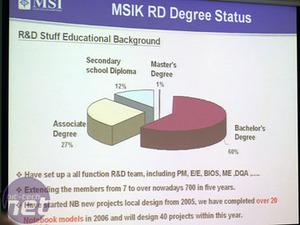

Just over 5,100 people work at the KunShan site, with the vast majority weighted towards the production lines of notebooks and motherboards. 715 make up the R&D staff which has a separate centre on site, and the rest are for material sourcing, QA, sales, customer service, administration and general management.

The site itself was founded only five years ago in 2002 and is currently only about 50 percent in use, with expected space for expansion as the company grows. Current space allocation is 172,000 square metres of work space, with 138,000 dedicated to manufacturing and another 100,000 for dormitories and entertainment. MSI also owns another site in ShenZhen in the south, which is 120,000 square metres and also makes (server) motherboards, VGA products and SmartPhones and there's always the head office in Jung-He, Taipei, Taiwan.

The facility is a 24 hour operation with three eight hour shifts per day, seven days a week. At this rate the KuShan facility can push out some 21,000 motherboards a month from the five lines in just one of the buildings. The other two buildings are dedicated to notebook production, CEM, sample production and system assembly.

The R&D team has grown 100 fold in the last five years and it splits its time between Design Support, Enterprise (Business) and Desktop Platform Solutions, Consumer Equipment (CE), Notebooks and other advanced technologies. The team has developed 20 motherboard SKUs since 2005 and produced designs for 40 notebooks in the last year, mostly for OEMs.

The production lines are a mix of machines and line workers progressively building up and testing the boards and products. There are no less than about 30 people that touch your motherboard before it gets boxed, and at least double that on the notebook side which requires more manual labour in its building. Couple in the fact your notebook has a motherboard inside it as well and that new notebook has been passed through some 100 pairs of (mostly gloved) hands even before you get your greasy mits on it.

Unfortunately we weren't allowed to take pictures in the facility itself, so you'll have to use your imagination I'm afraid.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.